SOURCE

Stuttgart Operated University Research Cubesat for Evaluation and Education

Was ist SOURCE?

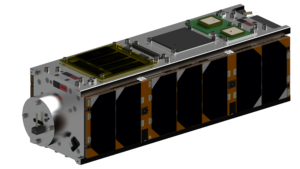

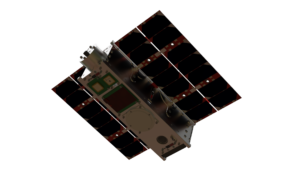

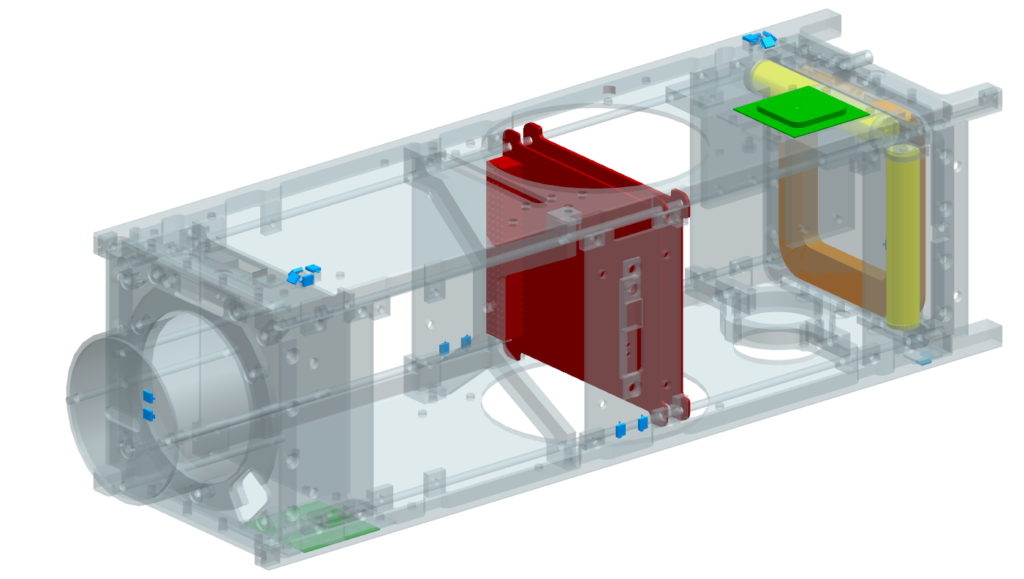

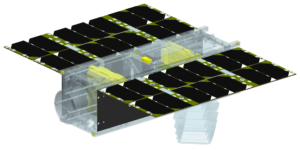

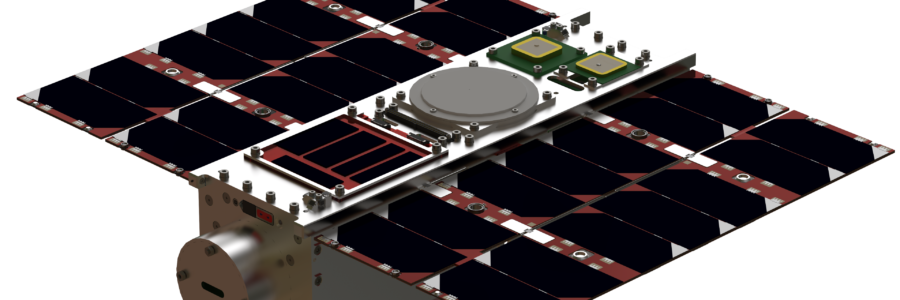

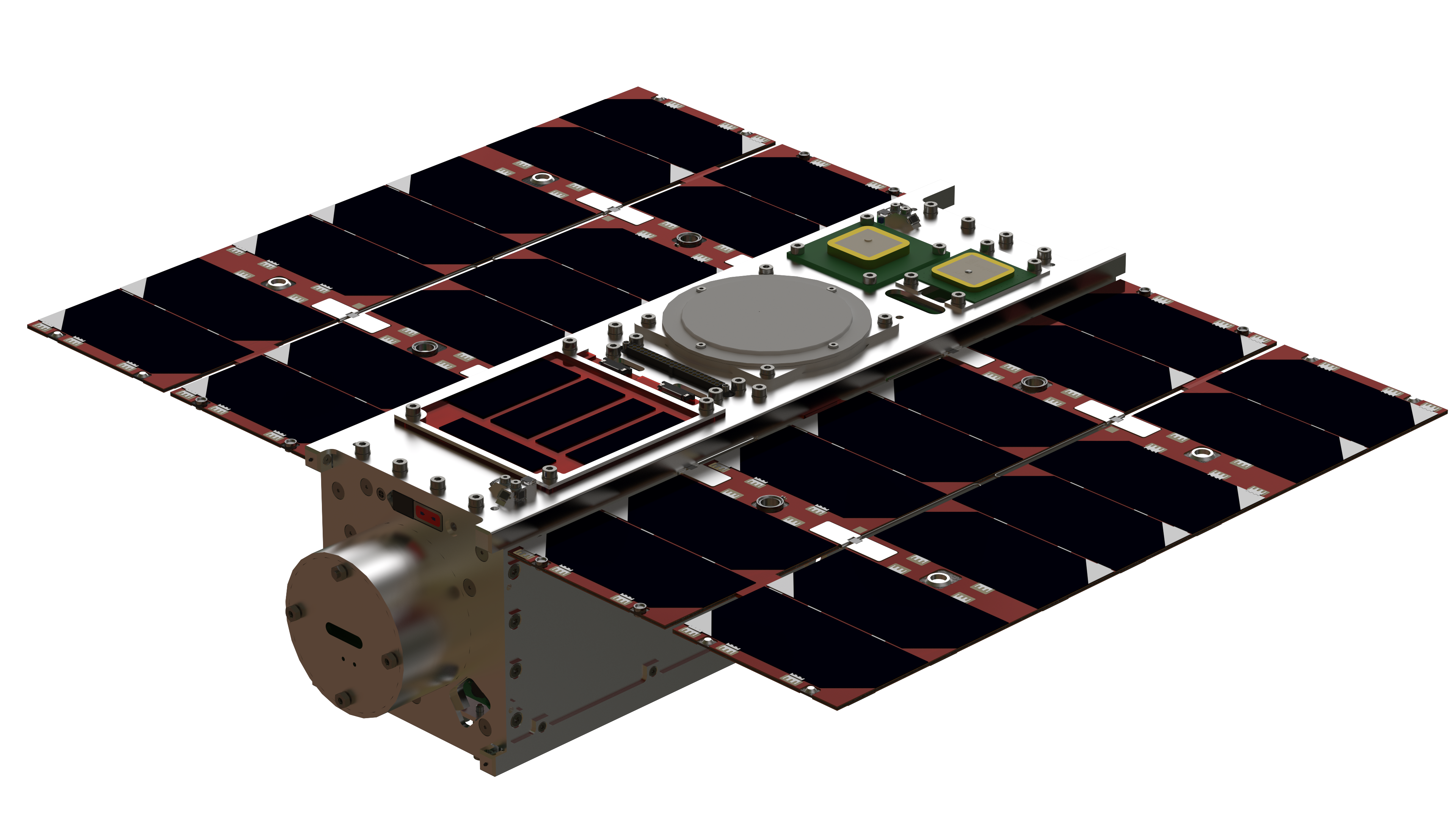

SOURCE (Stuttgart Operated University Research Cubesat for Evaluation and Education) ist ein Nanosatellit mit einer Größe von ca. 10 * 10 * 36 cm^3. Damit entspricht er dem 3U+ CubeSat Standard. Der Satellit wird in einer Kooperation zwischen Ksat e.V., dem Institut für Raumfahrtsysteme (IRS) der Universität Stuttgart entwickelt. Der Hauptteil der Entwicklungsarbeit wird von KSat Mitglieder und Studierenden der Universität Stuttgart durchgeführt. Viele Studierende kommen im Rahmen der Schlüsselqualifikation "Praktikum CubeSat-Technik" für ein Semester in das Team und erhalten Credits für ihre Arbeit am Satelliten. Das IRS finanziert das Projekt zu großen Teilen und unterstützt die Studierenden durch Mentoren für alle Subsysteme und durch Expertise, die unter anderem anderem durch Arbeit am Kleinsatelliten Flying Laptop aufgebaut wurde.

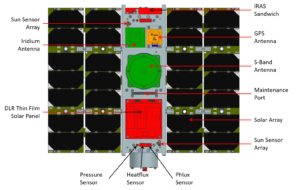

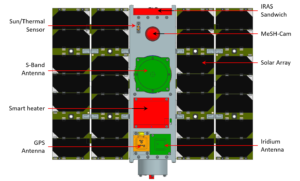

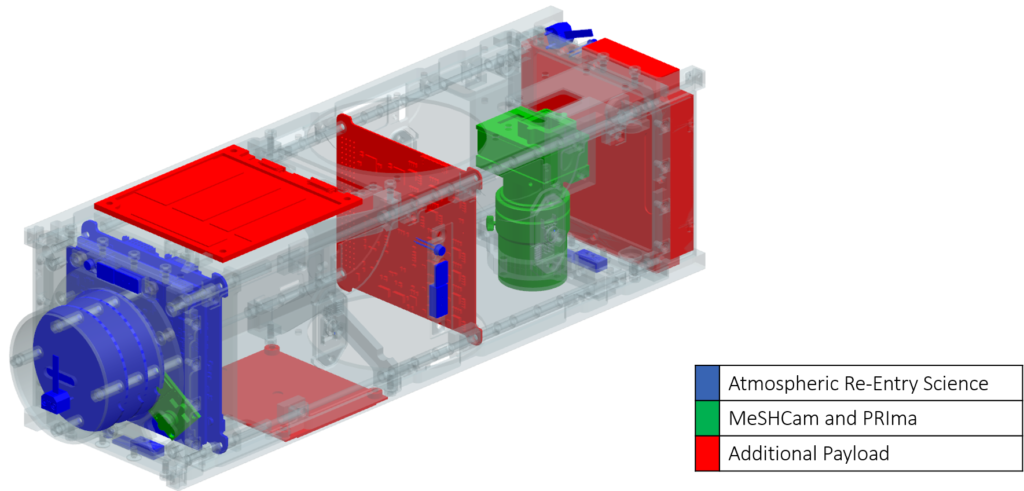

SOURCE trägt mehrere wissenschaftliche Nutzlasten. Eine Gruppe von Instrumenten dienen zur Untersuchung der Atmosphäre und des Wiedereintritts. Dazu gehören FIPEX Sensoren an der Vorder- und Rückseite, die die atomare Sauerstoffkonzentration in niedrigen Orbits unter 200km Höhe messen. Des Weiteren Wärmefluss- und Drucksensoren, die verteilt um den Satelliten, ebenfalls Daten zur Umgebung des CubeSats sammeln. Ein zweiter Bereich an Nutzlasten sind die Kameras an Board von SOURCE. Die „MeSHCam“ führt Meteorbeobachtung sowie Erdbeobachtung durch und wird zudem als Sternenkamera zur Lagebestimmung erprobt. Außerdem befindet sich eine kleinere Farbkamera an Bord, die "PRIma" (PR-Imager).

Weitere Technologiedemonstrationen als dritte Nutzlastgruppe für SOURCE stammen aus Kooperationen mit Industrie und Forschung. In diesem Rahmen wird im IRAS (Integrated Research Platform for Affordable Satellites) Projekt eine Entwicklungsplattform für Satelliten und neue Technologien geschaffen. Dazu zählen unter anderem ein neuartiges Verbundstoff-Sandwich und nicht speziell für die Raumfahrt entwickelte Sensoren sowie ein selbstregelnder Heizer. Zusammen mit dem Deutschen Zentrum für Luft- und Raumfahrt DLR werden zusätzlich Dünnfilmsolarzellen charakterisiert. All diese Komponenten sollen in den anspruchsvollen Bedingungen des Weltraums über den Missionszeitrum hinweg getestet werden.

Das Projekt befindet sich momentan in Phase D seines Entwicklungszyklus. Diese hat das Ziel alle Einzelteile, sowie das System als Ganzes im Bezug auf seine Funktionen und Widerstandsfähigkeit gegenüber der harten Weltraumumgebung und dem Start zu verifizieren. Ebenso steht die Softwareentwicklung im Zentrum dieser Phase. Seit März 2020 wird das Projekt mit der Unterstützung des Education Office der Europäischen Weltraumagentur ESA im Fly your Satellite!-Programm durchgeführt. Nach der erfolgreichen Teilnahme am Auswahlworkshop im Dezember 2019 wurde SOURCE als erstes deutsches Projekt gemeinsam mit zwei anderen Satelliten ausgewählt um an der dritten Ausgabe des Programms teilzunehmen. Dabei wird das Team durch Experten der ESA bei Entwicklung und Tests des Satelliten unterstützt. Höhepunkt des Programms ist der von der ESA organisierte Start in den Erdorbit, der aktuell für Anfang 2024 geplant ist. Mehr zum Fly Your Satellite!-Programm kann auf dessen Website gefunden werden.

Als Projekt an der Universität Stuttgart und Träger von Nutzlasten deren Entwicklung mit vom Land Baden-Württemberg unterstützt wurden, ist SOURCE als internationaler Botschafter für „Raumfahrt made in The LÄND“ auf Raumfahrtkongressen, der Expo Dubai und in der Forschung zu finden.

SOURCE ist „The SÄTELLITE“.

Subsysteme

Nutzlast

Die Nutzlast von SOURCE lässt sich in drei Gruppen unterteilen: Die atmosphärischen und Widereintritts - Sensorik, das Kamera System und die Komponenten des IRAS-Projekts.

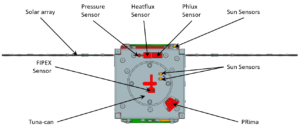

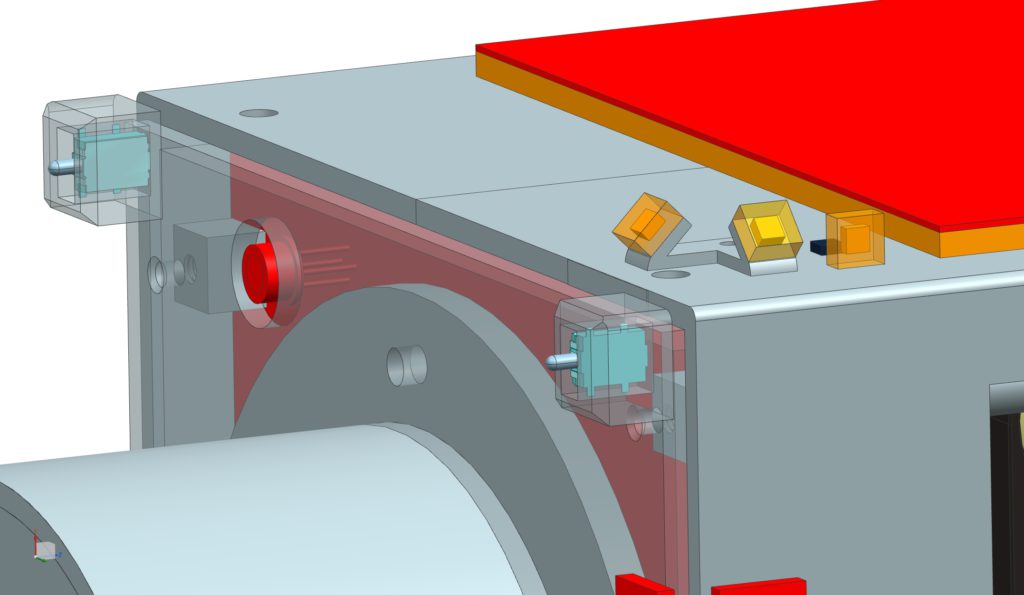

Das Ziel der atmosphärischen Sensorik ist es, Simulationen von Wiedereintrittsszenarien mit der Software PICLas zu verifizieren und zu verbessern. Um dies zu erreichen, werden zahlreiche Sensoren auf dem Satelliten platziert, welche über die Missionsdauer Messungen durchführen, mit einem Schwerpunkt auf den Wiedereintritt am Ende der Mission. Diese Sensorik bestehen aus Photodioden, Wärmeflussdichtesensoren, Drucksensoren sowie FIPEX-Sensoren welche atomaren und molekularen Sauerstoff messen können und am IRS entwickelt wurden.

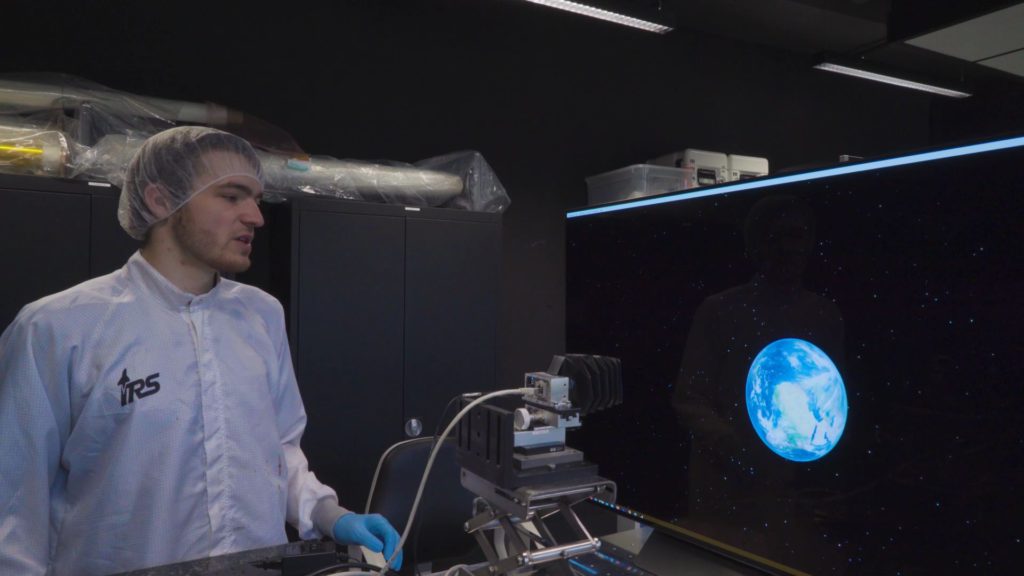

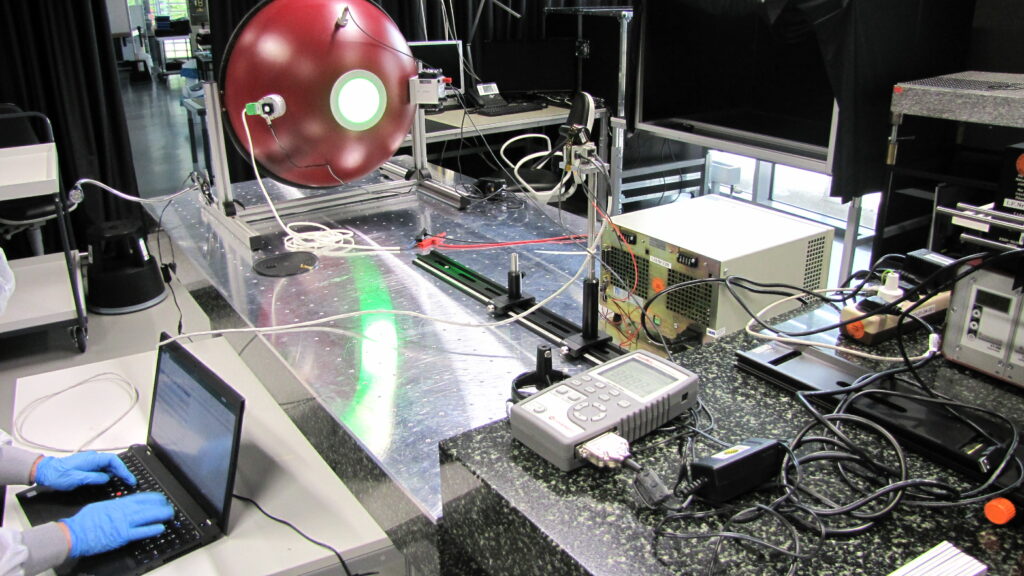

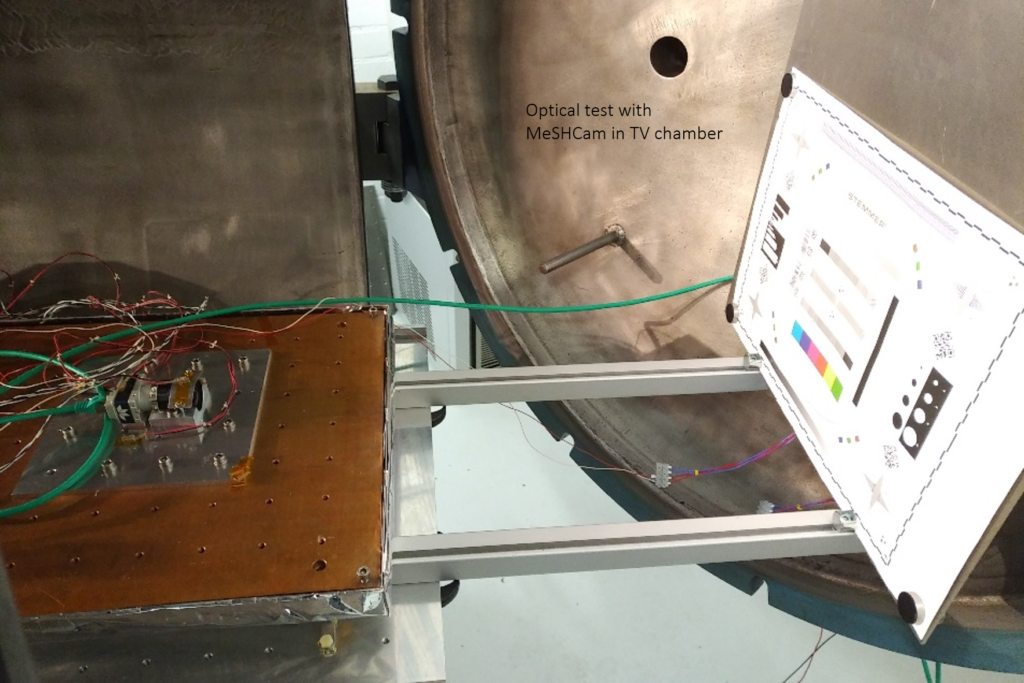

Mit dem Kamerasystem soll ein Star- und Horizontracker erprobt werden, sowie Meteore beobachtet werden um die Entstehung unseres Sonnensystems besser verstehen zu können und um das System für zukünftige Missionen zu testen. Da sich der Satellit oberhalb der Atmosphäre befindet kann er auch schwach leuchtende Meteore erfassen, deren Licht von Kameras am Boden nicht erfasst werden kann. Eine zweite Kamera, der "PR-Imager", kurz PRIma, soll zur Erdbeobachtung eingesetzt werden. Umgesetzt werden soll dies mit "Commercial off the shelf" (COTS) Teilen um diese für Raumfahrtanwendungen zu verifizieren.

Die dritte Gruppe der SOURCE Nutzlast besteht aus den Komponenten des IRAS-Projekts. Dessen Ziel ist es durch Verwendung von kommerziellen Bauteilen Satelliten günstiger herstellen zu können. Die Nutzlast des IRAS-Projekts auf SOURCE besteht aus effizienten Solarzellen von AzurSpace, einem Smart-Heater mit selbstregulierender Heizleistung und einer multifunktionalen Sandwichstruktur mit eingebauten Radiometern, Gyroskopen und Dehnungsmessstreifen.

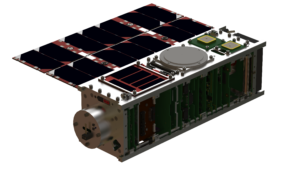

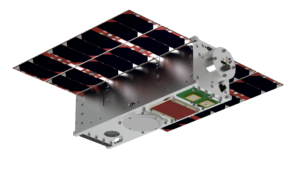

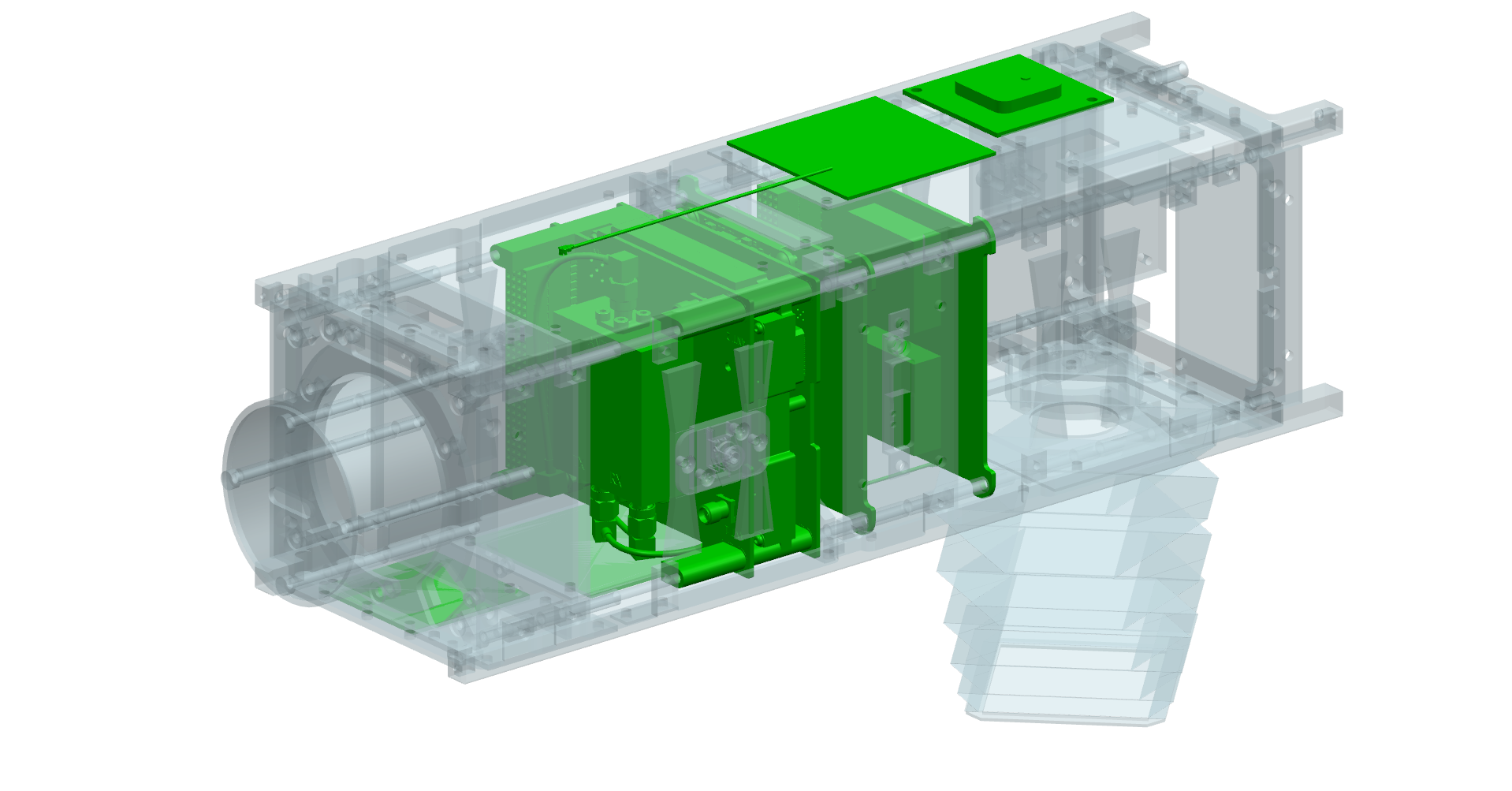

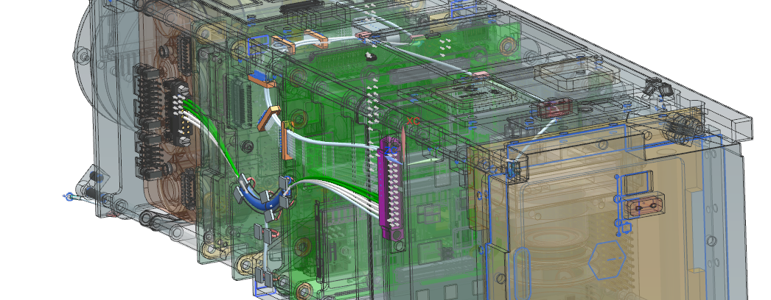

Struktur und Thermal

Das Subsystem Struktur beschäftigt sich mit dem physischen Aufbau des Satelliten und dem Hitzemanagement. Das Team muss die Komponenten aller Subsysteme im Satellit anordnen und sicherstellen, dass alle Komponenten hineinpassen und in ihrem zugelassenen Temperaturbereich bleiben. Außerdem entwickelt das Team die Ausfahrmechanismen der Solarzellen.

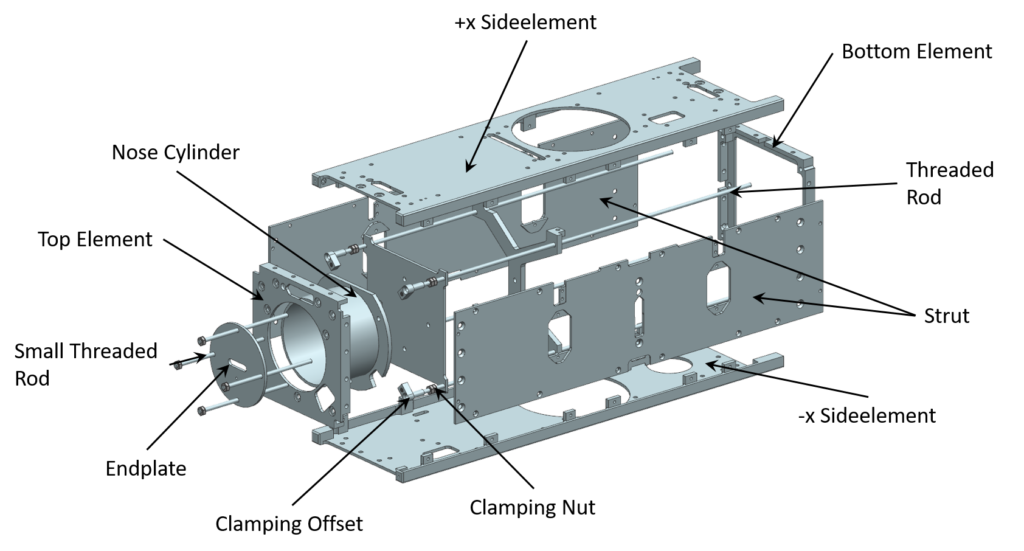

Die Primärstruktur ist das Rückgrat des Satelliten und nimmt die Experimente sowie deren Versorgungssysteme an Bord auf. Alle im CubeSat verbauten Platinen werden auf vier Gewindestangen gestapelt und mit einem Mechanismus verspannt. Anschließend werden Solarpaneele, Antennen und Experimente auf den Außenseiten angeschraubt. Alle elektronischen Komponenten werden durch Thermalsensoren überwacht und durch Heizer im zugelassenen Temperaturbereich gehalten. FEM- und Thermalsimulationen analysieren das Verhalten des Satelliten während Start und Betrieb. Derzeit werden die Primärstruktur und Testhalterungen für die Fertigung vorbereitet und ein Zusammenbau- und Integrationskonzept ausgearbeitet. Nach dem Zusammenbau wird der Prototyp in mehreren Shakertests den Startbedingungen ausgesetzt.

Eine weitere Aufgabe des Teams ist das Design der Auswurfschalter. Sie registrieren wenn der Satellit den Startbehälter an der Rakete verlässt und aktivieren dann den Satelliten.

Lageregelungssystem

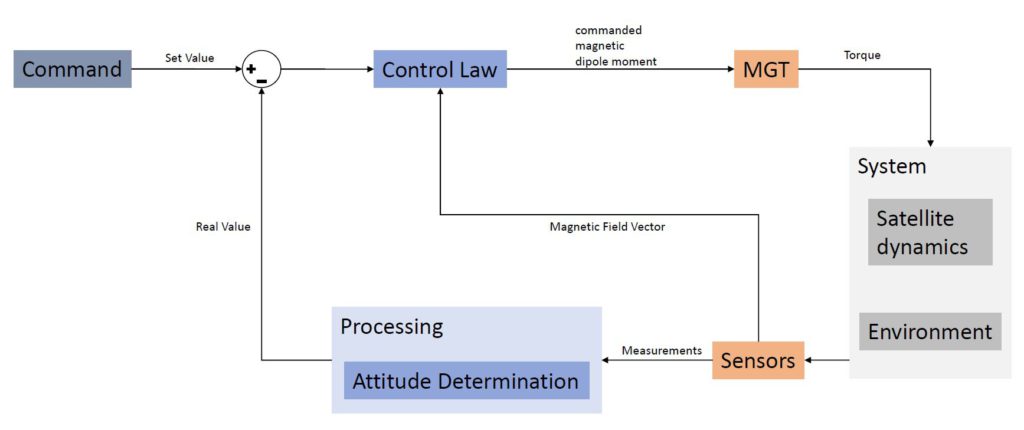

Das Attitude Control System (ACS) beschäftigt sich mit der Kontrolle der Ausrichtung des Satelliten. Nach dem Auswurf von der Rakete muss es den Satelliten stabilisieren. Während der Operationsphase müssen die Solarzellen zuverlässig zur Sonne ausgerichtet werden und gelegentlich die Kamera zur Erde gedreht werden. Dafür und um Kontext für Nutzlastmessungen bereitzustellen muss die Lage des Satelliten präzise an Bord bestimmt werden.

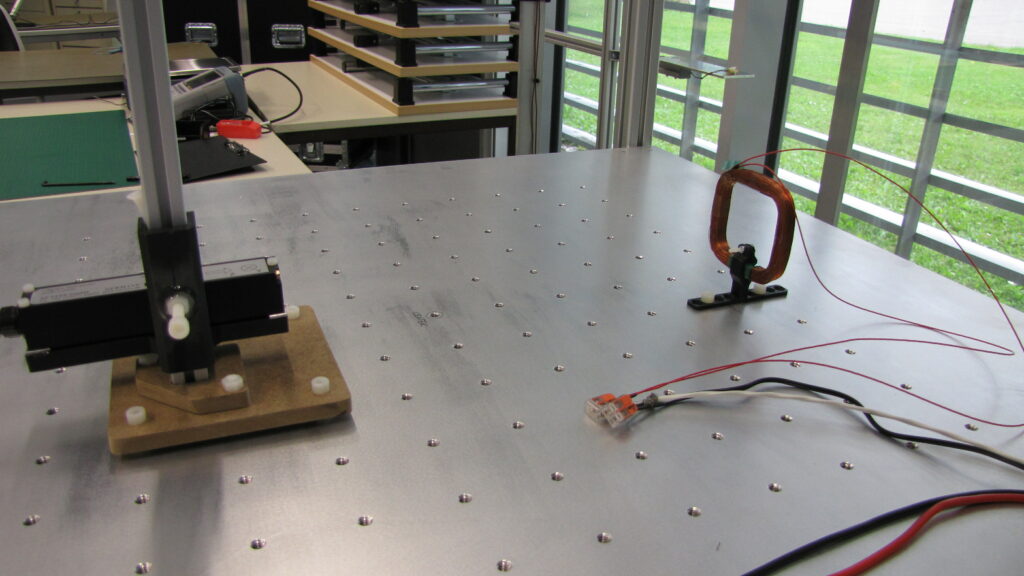

SOURCE verwendet zur Kontrolle seiner Lage Magnetorquer. Das sind Magnetspulen, die ein Magnetfeld aufbauen, das sich ähnlich wie ein Kompass, zum Erdmagnetfeld ausrichten möchte. Dadurch kann ein Drehmoment erzeugt und der Satellit gesteuert werden. Nur mit Magnetorquern kann allerdings kein Drehmoment um den Magnetfeldvektor aufgebaut werden. Dadurch kann der Satellit zu jedem Zeitpunkt nur in zwei Achsen kontrolliert werden. Allerdings bewegt er sich in seinem Orbit durch verschiedene Bereiche des Erdmagnetfelds und kann so im Laufe der Zeit in allen drei Achsen gesteuert werden. Die Magnetorquer für SOURCE sind selbst gebaut und wurden vollständig von Studierenden entwickelt. Zwei sind als zylindrische Spulen mit Ferritkernen, die dritte als quadratische Flachspule konstruiert. Prototypen wurden bereits mit ausgezeichneter Performance getestet.

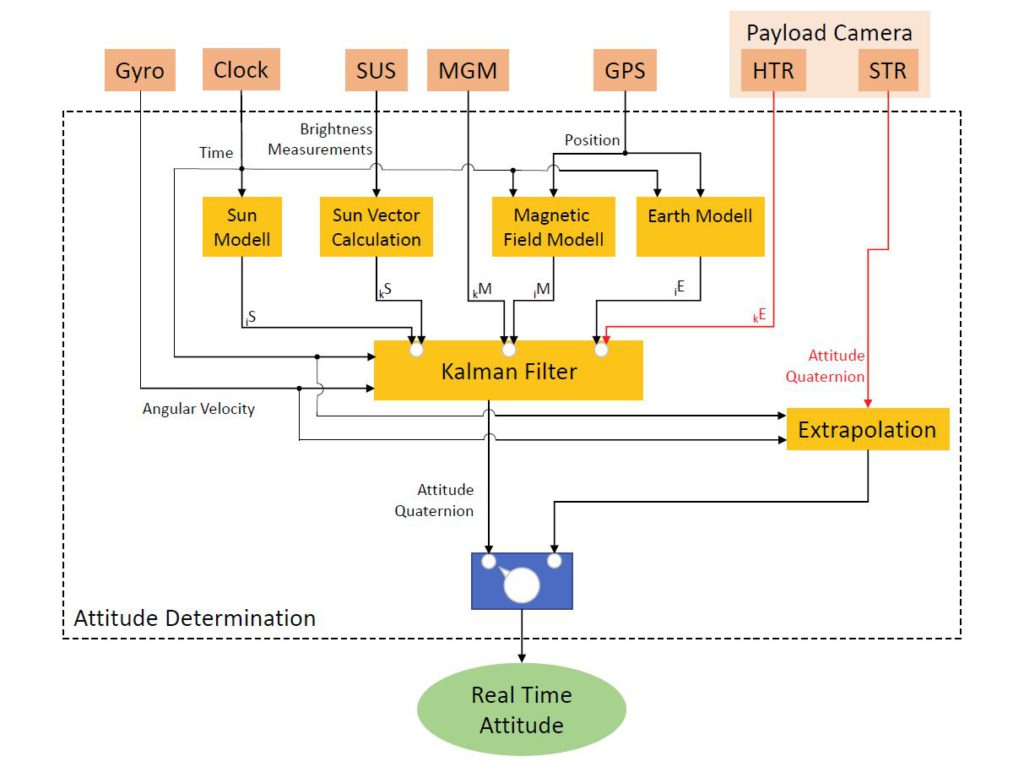

Zur Bestimmung der Lage werden hauptsächlich Sonnensensoren, Magnetometer, GPS und Gyroskope verwendet. Die Messungen von Sonnensensoren und Magnetometern werden jeweils mit einem Sonnenmodell bzw. einem Modell des Erdmagnetfelds verglichen. Das lokale Magnetfeld hängt stark von der Position des Satelliten ab. Diese wird durch die Daten des GPS bestimmt. Die Messungen aller Sensoren werden in einem Kalman-Filter zu einer Lage kombiniert.

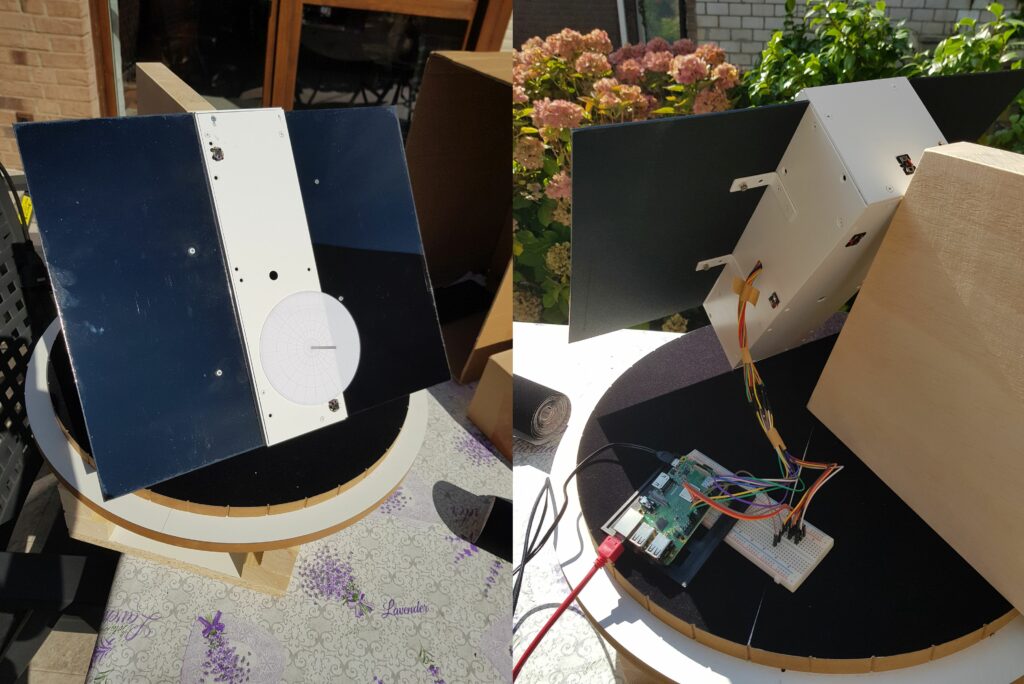

Neben diesen für CubeSats typischen Sensoren soll auch erprobt werden die Erdbeobachtungskamera als Sensor für die Lageregelung zu benutzen. Sie soll als Sternkamera Bilder vom Sternenhimmel aufnehmen und dann durch Abgleichen der Bilder mit einem Sternkatalog die Lage bestimmen. Stern- und Horizontkameras sind keine neue Idee und werden seit Jahrzehnten in der Raumfahrt verwendet. Eine kommerzielle Erdbeobachtungskamera für diese Aufgabe zu verwenden ist allerdings bisher nur wenig erprobt worden und verspricht im Erfolgsfall eine deutliche Verbesserung der Genauigkeit der Lagebestimmung, ohne große zusätzliche Kosten. Da die Kamera allerdings bei SOURCE eine Technologiedemonstration ist, muss das Lageregelungssystem auch ohne sie funktionieren.

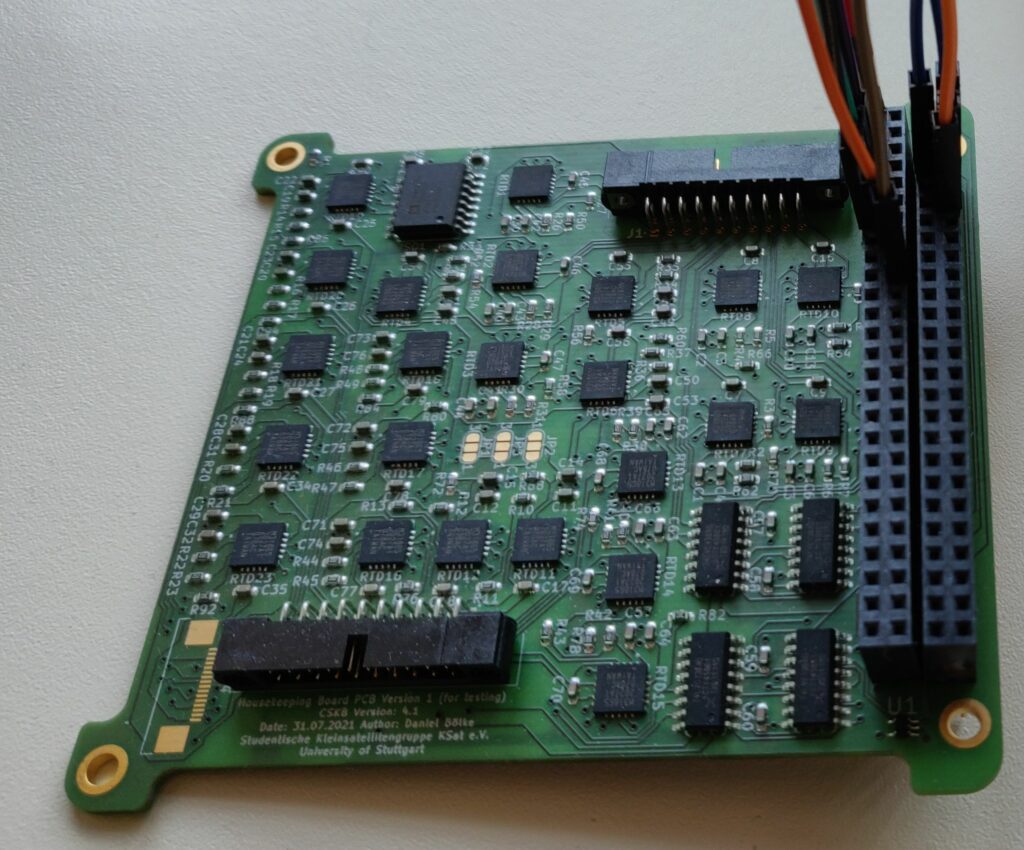

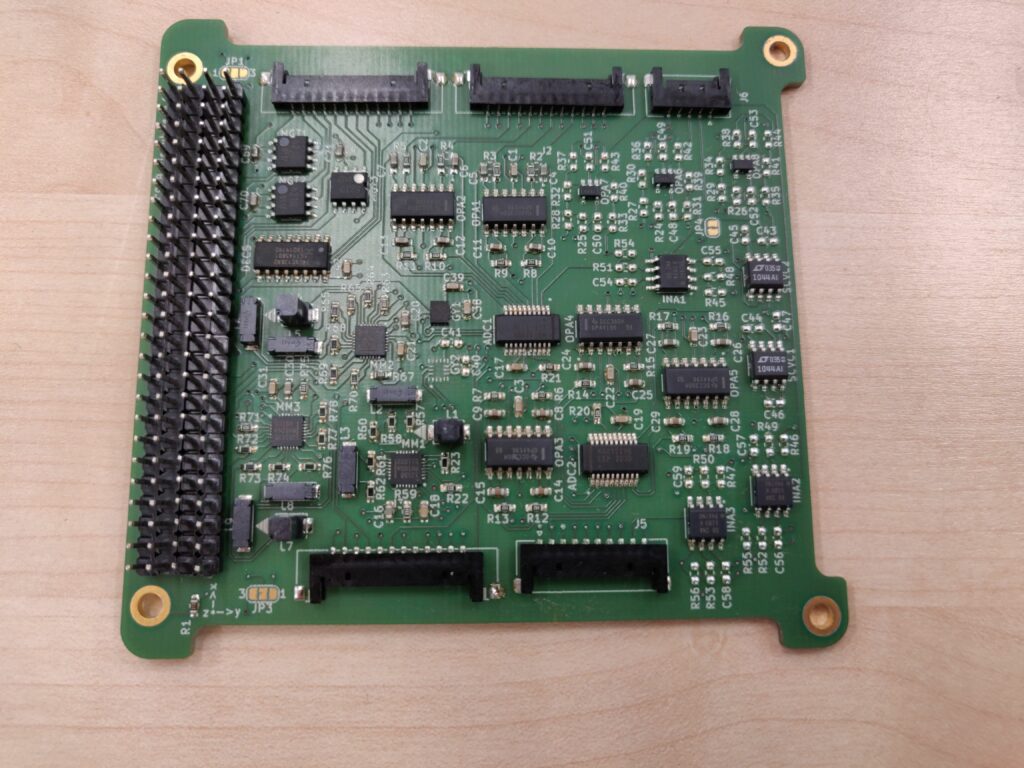

Die Sensoren, Sonnensensormesselektronik und Magnetorquerkontrolle sind auf den beiden Housekeepingboards im Satelliten untergebracht. Prototypen dieser Platinen werden aktuell gebaut und getestet.

Die Software für die Lageregelung wird in einer Matlab-Simulink basierten Simulationsumgebung entwickelt. Die Regelgesetze für Lagestabilisierung, Sonnenausrichtung und Kameraaufnahmen sind getestet und funktionieren. Sie müssen allerdings noch weiter optimiert werden wenn die genauen Hardwareeigenschaften und der finale Orbit bekannt sind. Die Simulation beinhaltet außerdem die Algorithmen für die Auswertung der Sonnensensordaten, Lagebestimmung und Bestimmung der Zielausrichtung.

Onboard Data Handling

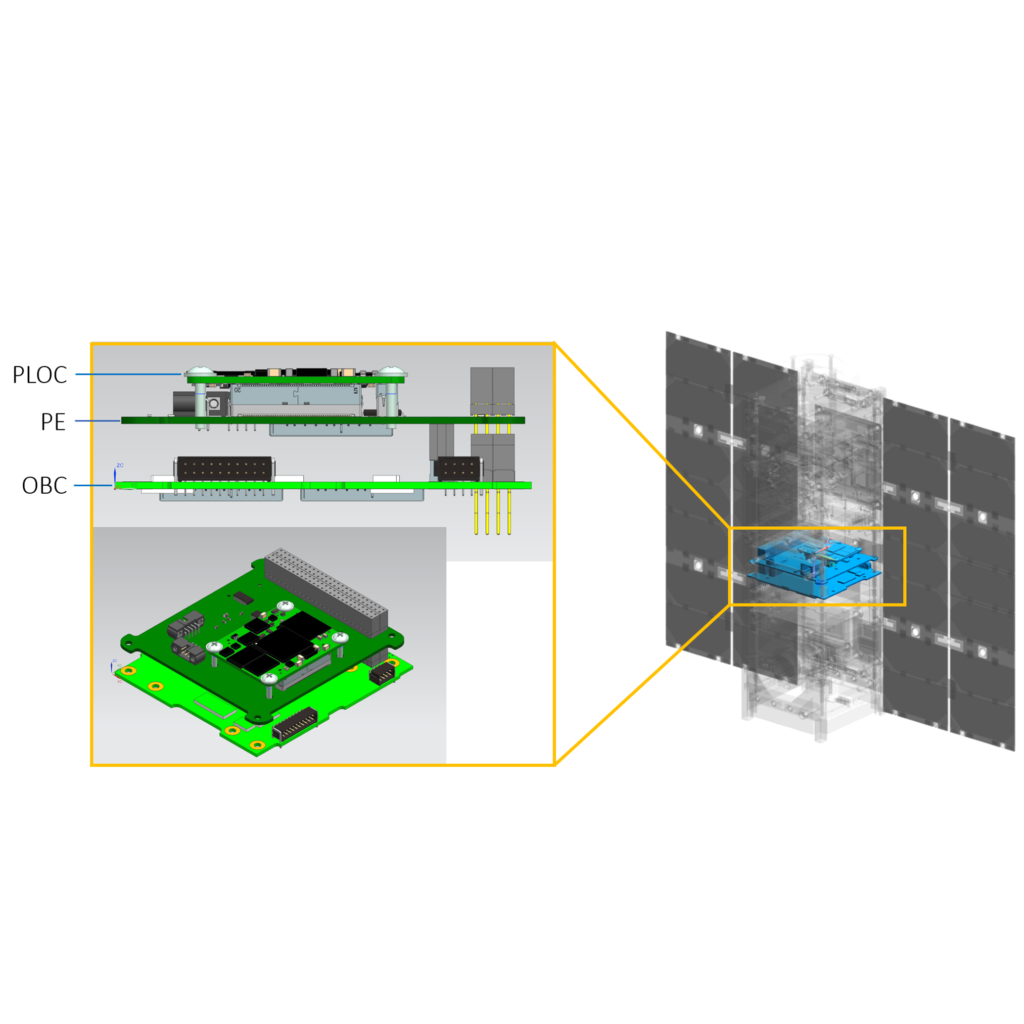

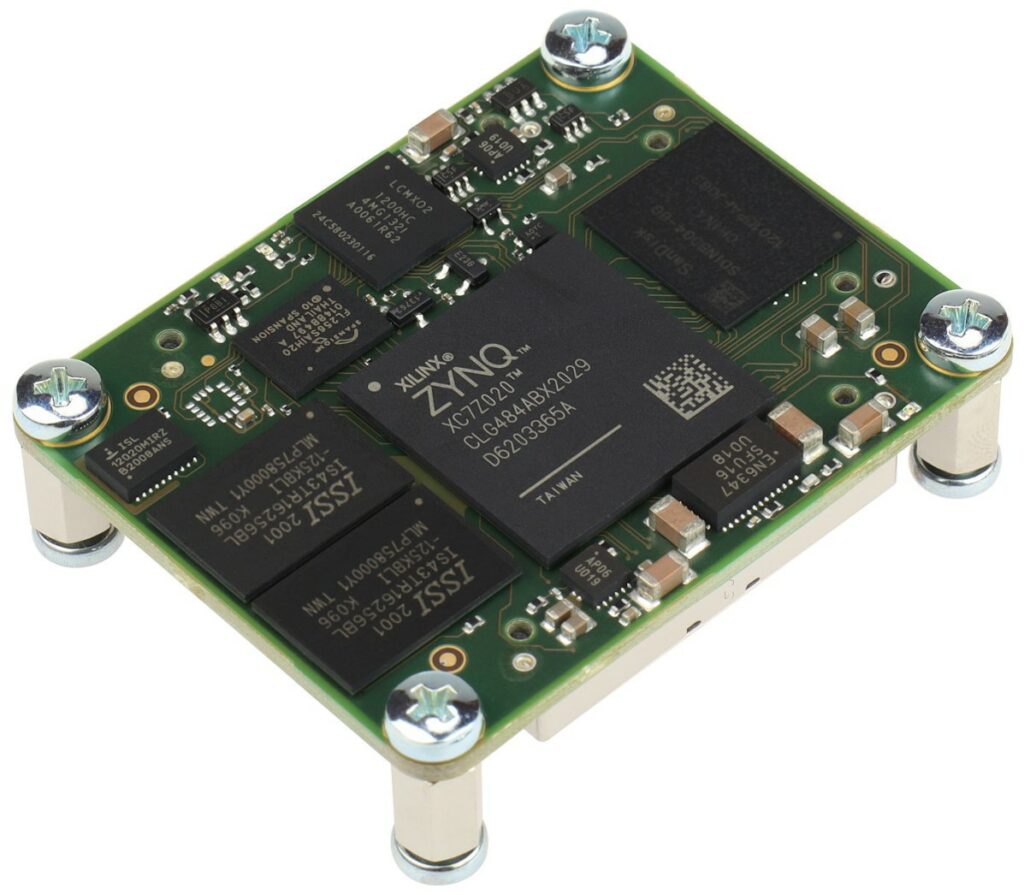

Das Subsystem On-Board and Data Handling ist die zentrale Steuereinheit des CubeSats. Von hier aus werden Befehle verteilt, der Zustand des gesamten Satelliten überwacht und Ereignisse protokolliert. Der für die Umsetzung der Anforderungen eingesetzte On Board Computer besteht im Wesentlichen aus einem Mikrocontroller, verschiedenen Speichereinheiten und Schnittstellen für die Kommunikation mit anderen Subsystemen.

Zu den grundsätzlichen Aufgaben zählt:

- das Speichern von Housekeeping Daten.

- das Speichern und Verarbeiten von Nutzlastdaten.

- das Kommandieren der Satellitenmodi.

- die Berechnung von Steuerbefehlen zur Lagereglung.

- das Erkennen und gegebenenfalls das Beheben von Fehlfunktionen angeschlossener Geräte.

- das Ausführen von Befehlen der Bodenstation.

- das Aufbereiten von Daten für die Übertragung zur Bodenstation.

Hardware

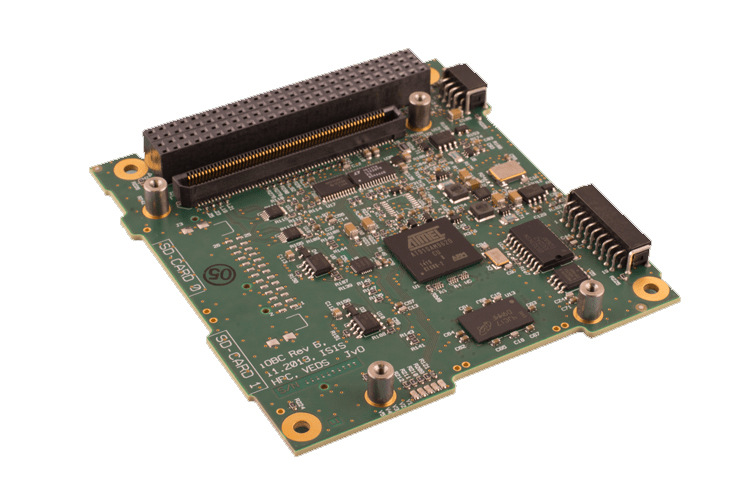

Als On-Board Computer mit ausreichend Rechenleistung und Speicherkapazität um die Aufgaben zuverlässig ausführen zu können wird der iOBC (ISIS On Board Computer) eingesetzt.

- 400 MHz ARM9 Prozessor

- Arbeitsspeicher: 32MB SDRAM

- Massenspeicher: 2x2GB SD cards

- Softwarespeicher: 1MB NOR Flash

- Speicher für kritische Daten: 256KB FRAM

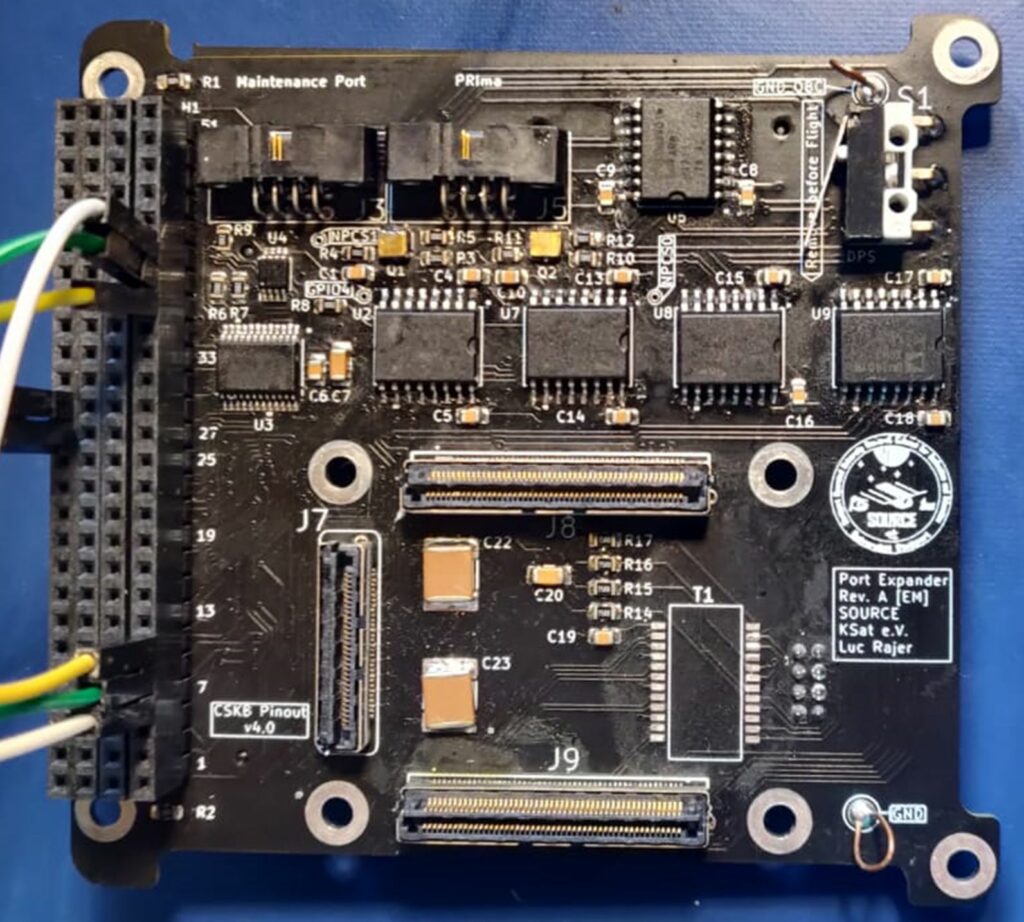

Der "Port Expander" ist eine selbst entwickelte Platine, die über dem OBC sitzt. Seine Aufgaben sind die Konvertierung von Signalen, die Weitergabe von Verbindungen zum OBC, die Erhöhung der Schnittstellenanzahl und die Verbindung zum Payload On-Board Computer. Der Port Expander verbindet außerdem den OBC mit dem CubeSat-Kitbus, der Hauptsteckerreihe die durch den gesamten Satelliten läuft und alle Platinen miteinander verbindet.

Für die Signalübertragung zwischen Komponenten werden diverse Protokolle verwendet. In Verbindung mit dem RS485-Bus verwenden wir das standardisierte "space date link protocol". Ein weiterer wichtiger Bus ist das Serial Peripheral Interface (SPI), mit dem über 30 Geräte an den OBC angeschlossen werden. Außerdem wird noch USB und Gigabit Ethernet verwendet um den Payload On-Board Computer mit dem OBC zu verbinden (über den Port Expander).

Software

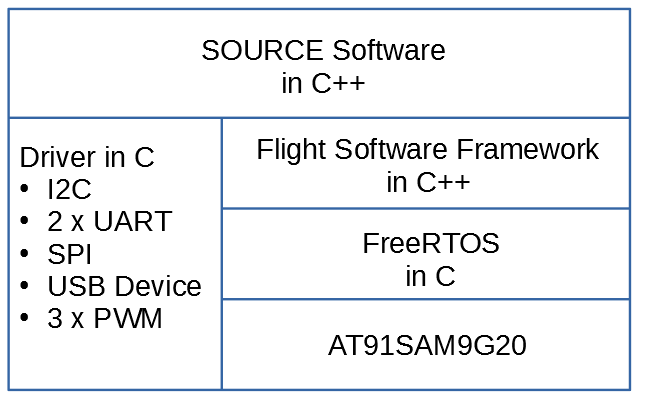

Die Abbildung „Softwarearchitektur“ zeigt den grundsätzlichen Aufbau der On‑Board Software von SOURCE. Der AT91SAM9G20 stellt dabei die physikalische Schicht in der Architektur dar worauf unter Verwendung eines Timers das Echtzeitbetriebssystem FreeRTOS aufbaut. Durch FreeRTOS kann ein Programm in mehrere Prozesse aufgeteilt werden. Der Zugriff auf prozessorinterne Ressourcen der jeweiligen Prozesse wird dabei von FreeRTOS verwaltet. Anders als bei Standard‑Betriebssystemen kann ein Prozess mit niedrigerer Priorität niemals vor einem Prozess mit höherer Priorität ausgeführt werden. Dies ist essenziell um Echtzeitanforderungen an die Software gewährleisten zu können.

Des Weiteren basiert die Software auf einem am Institut für Raumfahrtsysteme entwickelten Flight Software Framework (FSFW), das bereits im Kleinsatelliten Flying Laptop erfolgreich eingesetzt wird. Das FSFW stellt mehrere Bausteine und Vorlagen für Softwarekomponenten in Form von abstrakten Klassen zur Verfügung wodurch die Entwicklungszeit reduziert und die Zuverlässigkeit der Software erhöht wird. So gibt es beispielsweise ein Unterframework, welches das Programmieren von PUS Services erleichtert. PUS steht für Packet Utilization Standard und ist ein von der ESA entwickelter Standard, der eine Reihe missionsübergreifender Services für den Satellitenbetrieb definiert. Zusätzlich wird die Paketstruktur der Daten durch den Standard festgelegt wodurch Kompatibilität zwischen verschiedenen Bodenstationen und Satelliten erreicht wird. Wir verwenden die Programmiersprache C++ um die Software zu implementieren.

Electrical Power System

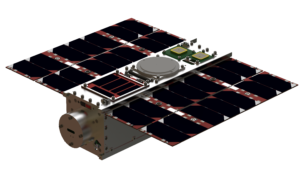

Die Hauptaufgabe des Electrical Power System (EPS) ist die Stromerzeugung, Energiespeicherung und Verteilung des Stroms an andere Subsysteme. Außerdem muss sie Strom liefern, um die Solarzellen zu entfalten und den Satelliten zu aktivieren. Das EPS von SOURCE benötigt im Vergleich zu vielen CubeSat-Missionen einige erweiterte Funktionalitäten. Daher wurde die Konfiguration der Solarzellenpaneele und die PCDU (Power Conditioning and Distribution Unit) selbst entwickelt.

Insgesamt 56 Solarzellen liefern unter idealen Bedingungen bis zu 32 W, die in einer 75 Wh weltraumqualifizierten Lithium-Ionen-Batterie von Gomspace gespeichert werden können. Um die Leistung der Solarzellen zu maximieren, führt die PCDU ein Maximum Power Point Tracking (MPPT) durch. Dies wird von einem strahlungsharten Mikrocontroller (Vorago 10820) gesteuert. Der Mikrocontroller steuert auch das Umschalten zwischen den verschiedenen CubeSat-Modi (wie vom OBC kommandiert) und die einzelnen Ausgange. Es gibt 32 schaltbare Ausgänge, die jedes Subsystem und jede Komponente des CubeSat steuern. Zusätzlich wird der Stromverbrauch der Subsysteme auf Überströme und der Zustand des OBC überwacht. Dieser kann im Falle eines Fehlers neu gestartet werden. Die PCDU kann auch direkt über das Kommunikations-Subsystem vom Boden aus mit so genannten High Priority Commands kommandiert werden, die entweder das Kommunikations-Subsystem, den OBC oder den gesamten Satelliten neustarten können.

Das EPS ist für den Erfolg der Mission von entscheidender Bedeutung, weshalb so weit wie möglich Redundanzen und ausfallsichere Komponenten eingesetzt werden. Deshalb wird eine Mischung aus COTS- und weltraumqualifizierten Komponenten verwendet.

Kommunikation

Das Kommunikationssystem hat drei Aufgaben:

- Kommandos zur Steuerung des Satelliten empfangen

- Statusinformationen zum Boden senden

- Nutzlastdaten übertragen

Die ersten beiden Aufgaben sind besonders kritisch für die Mission, da Fehler in den Kommandos schnell zum Versagen des Satelliten führen können. Bei Nutzlastdaten zählt dagegen die erreichbare Datenrate mehr. Es sind bis zu 1 Mbit/s geplant.

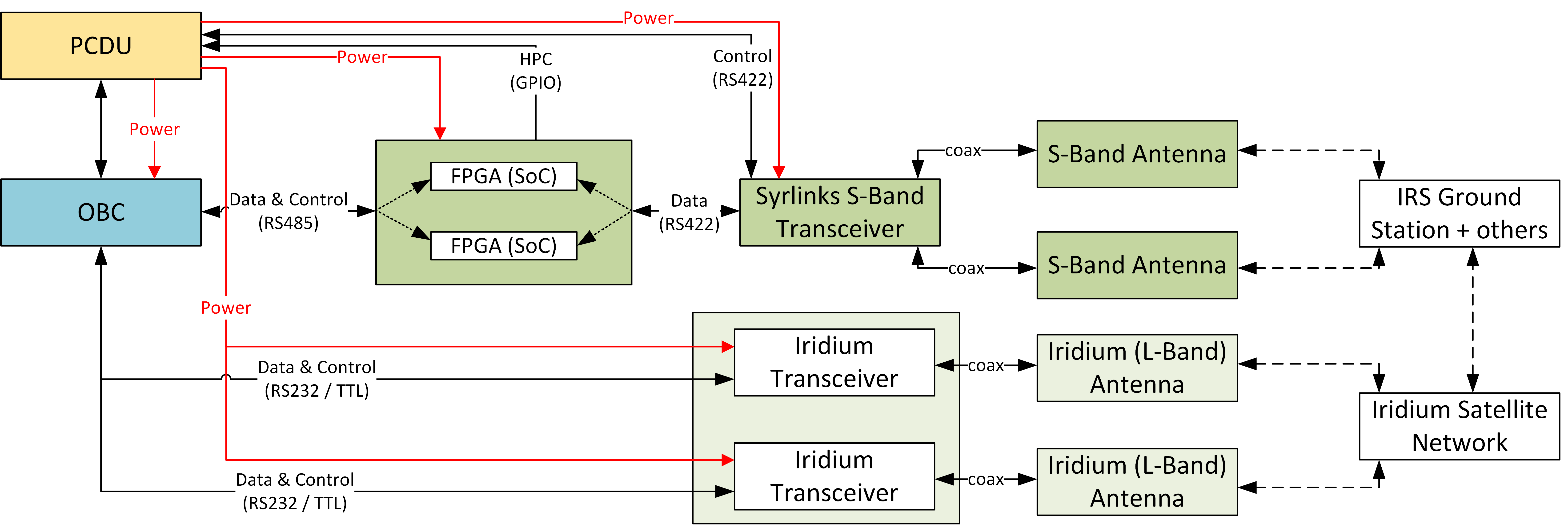

Die Datenübertragung geschieht per Funk. Für die direkte Kommunikation zwischen der Bodenstation des IRS und SOURCE werden Frequenzen im S-Band (2 – 2,4 GHz) verwendet. Auch andere Bodenstationen unserer Partner weltweit können damit erreicht werden. Traditionell kam diese Technik eher bei größeren Satelliten zum Einsatz, findet nun aber auch Anwendung in CubeSats.

Im Uplink, d. h. von der Bodenstation zum Satelliten, liegt die Trägerfrequenz bei 2083.4 MHz. Im Downlink, d. h. vom Satelliten zur Bodenstation, wurden 2263.1 MHz gewählt. Der Uplink kommt mit einer geringen Datenrate von 16 kbit/s aus, während der Downlink zwei Modi mit 200 kbit/s und 1 Mbit/s hat.

Die gewählten Frequenzen müssen international abgestimmt werden, um Interferenzen zu vermeiden. Das S-Band wird z. B. auch für WLAN genutzt. Das geschieht mittels der ITU, der International Telecommunications Union, welche das komplette Frequenzspektrum weltweit verwaltet.

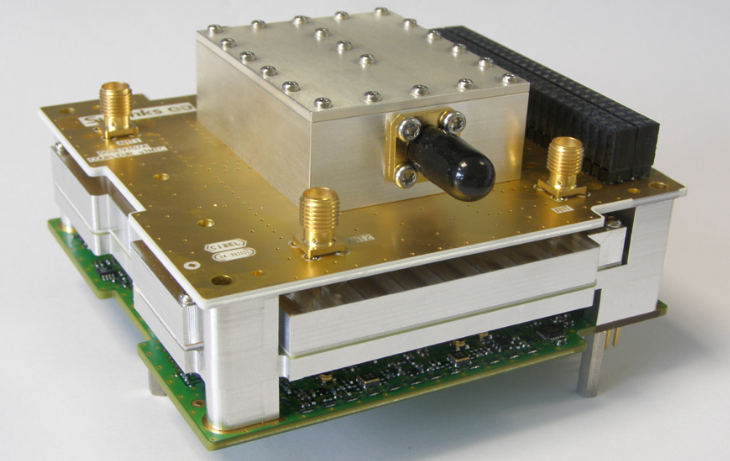

Am Satelliten werden ankommende Funksignale über zwei Patchantennen empfangen. Sie sind für Signale aus allen Richtungen empfindlich. Die Signale werden an einen Transceiver weitergeleitet, der diese in Computer-Kompatible Daten umwandelt. Die entgegengesetzte Richtung, der Downlink, funktioniert umgekehrt. Daraus ergibt sich der Name des Transceivers: Empfänger „Receiver“ und Sender „Transmitter“. Verwendet wird ein Transceiver der Firma Syrlinks geplant, mit der Modellbezeichnung EWC31.

Die übertragenen Daten werden in zusätzliche Protokolle verpackt und mit bestimmten Algorithmen codiert, um die Zuverlässigkeit der Übertragung zu steigern. Falsch empfangene Daten können so korrigiert oder verworfen werden. Dabei orientieren wir uns an internationalen Standards des CCSDS. Diese machen unser System zudem mit anderen Betreibern kompatibel. Für die sehr rechenintensive Codierung kommen zwei FPGAs zum Einsatz.

Es werden die folgenden CCSDS-Standards beachtet:

- Radio Frequency and Modulation Systems (CCSDS 401.0-B-28)

- TC Synchronization and Channel Coding (CCSDS 231.0-B-3)

- TM Synchronization and Channel Coding (CCSDS 131.0-B-3)

- TC Space Data Link Protocol (CCSDS 232.0-B-3)

- TM Space Data Link Protocol (CCSDS 132.0-B-2)

Während des Wiedereintritts – der den Satelliten zerstören wird – kann es passieren, dass SOURCE keine Bodenstation in Sicht hat, beispielsweise über dem Pazifik. Um die wertvollen Messdaten trotzdem zu übertragen ist das sekundäre Kommunikationssystem vorgesehen. Hier werden im L-Band (1 – 2 GHz) kurze Nachrichten, ähnlich einer SMS, an kommerzielle Satellitenkonstellationen wie Iridium gesendet.

Dadurch wird die Möglichkeit Daten zu übertragen unabhängig von der aktuellen Position von SOURCE. Diese Fähigkeit ist für CubeSats selten. Iridium betreibt eine Konstellation aus 66 Satelliten, die primär für Satellitentelefone eingesetzt werden. Die genauen Frequenzen liegen im Bereich 1616 – 1626.5 MHz. Der Transceiver auf SOURCE, genannt Iridium 9603, ist eigentlich für handelsübliche Satellitentelefone gedacht. Daher muss er vor dem Flug umfangreich getestet werden.

Operations and Ground

Das Subsystem Operations and Ground Systems (OPS&GRND) beschäftigt sich mit dem geplanten Betrieb des Satelliten und der benötigten Bodeninfrastruktur. Zum Bodensegment zählt die Bodenstation, das Mission Control System, das Mission Planning Tool und das Flight Dynamics Tool.

SOURCE wird die Bodenstation des IRS verwenden, welche bereits in Betrieb ist und für den Satelliten Flying Laptop benutzt wird. Hierfür ist es jedoch notwendig, die existierende Schnittstellensoftware der Bodenstation zu überarbeiten, damit diese auch für SOURCE genutzt werden kann. Das Missionsplanungs-Tool wird momentan entwickelt und als Mission Control System (MCS) wird ein ähnliche Infrastruktur wie bei den anderen laufenden Satellitenprojekten des Instituts verwendet. Das Flugdynamik-Tool dient einerseits der Auswertung der Navigationsdaten und andererseits liefert es essentielle Daten für die Missionsplanung, beispielsweise wann SOURCE über welche Koordinaten fliegt. Das Subsystem arbeitet außerdem daran so viele Arbeitsschritte wie möglich zu automatisieren, um den späteren Betrieb des Satelliten zu erleichtern.

Außerdem befasst sich OPS&GRND mit der Erstellung des Benutzerhandbuchs des Satelliten, sowie der Erstellung der Satellitenreferenzdatenbank (eine Art Wörterbuch) um zwischen Satelliten und Bodensegment zu übersetzen. Darüber hinaus unterstützt OPS&GRND die Erstellung von Prozeduren und deren Tests sowie der entsprechenden Anpassung an betriebliche Randbedingungen. In Vorbereitung auf den Betrieb müssen verschiedene Szenarien simuliert und ein Zeitplan erstellt werden, um einen sicheren Betrieb des Satelliten und somit den Erfolg der Mission zu gewährleisten. Das entsprechende Training der anfänglichen missionskritischen Launch and Early Orbit Phase wird in enger Kooperation mit Testbed durchgeführt.

Testbed

Das Subsystem Testbed hat zwei Kernaufgaben. Zum einen soll es eine Plattform für gemeinsame Tests aller Komponenten bereitstellen. Zum anderen soll ein Simulator entwickelt werden, mit welchem die Satellitensoftware getestet wird.

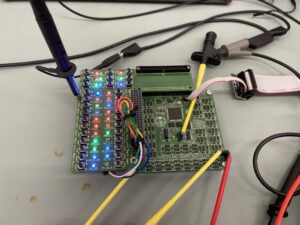

Die integrierten Tests aller Komponenten werden auf dem sogenannten "FlatSat" durchgeführt. Dieser stellt einen nahezu kompletten Aufbau des Satelliten im Reinraum dar. Damit können die Komponenten, die bis dahin lediglich separat geprüft worden sind, im Verbund betrieben und getestet werden. Dies ist besonders wichtig, um etwaige Fehler auf dem Satellitenbus, an dem alle Geräte hängen, auszuschließen. Durch den speziellen Aufbau des FlatSats, nämlich im "flachen" (flat), können an einzelnen Bauteilen Messungen durchgeführt werden oder diese sogar leicht getauscht werden.

Im Simulator kann man den Satelliten virtuell "fliegen" zu lassen. Hierfür werden die wichtigsten Bauteile (Batterie, Solarzellen, Gyroskop etc.) als programmierte Modelle erstellt. Diese erzeugen Ausgabedaten, welche wiederum in den On-Board-Computer (OBC) eingespielt werden können. Somit können Ausfälle von Komponenten simuliert werden oder kritische Modi getestet werden, ohne echte Hardware im Grenzbereich betreiben zu müssen. Außerdem können Daten wie aus dem Orbit generiert werden, während die Hardware sich am Boden befindet.

Damit die OBC am FlatSat mit dem Simulator Daten austauschen kann, wird auch an einem speziellen Interface gearbeitet. Damit dieses korrekt mit dem OBC funktionieren kann, muss auf verschiedene Größen geachtet werden, besonders auf die Latenz zwischen Anfrage und Antwort.

Neben den notwendigen Tests des Satelliten-Systems bietet das "Testbed" (Zusammenspiel von FlatSat und Simulator) dem Team von Operations eine Möglichkeit, die Missionsabschnitte des Satellitens zu verifizieren und Personen für den späteren Betrieb zu trainieren.

Partner, Sponsoren & Unterstützer

IRS

Institut für Raumfahrtsysteme der Universität Stuttgart

DLR Stuttgart e.V.

Deutsches Zentrum für Luft- und Raumfahrt

DLR Bremen e.V.

Deutsches Zentrum für Luft- und Raumfahrt

DLR GSOC

Deutsches Raumfahrt-kontrollzentrum des DLR

AIRBUS

AIRBUS Defence and Space

Fraunhofer IPA

Fraunhofer-Institut für Produktionstechnik und Automatisierung

STI

Space Tech GmbH

Azur Space

Azur Space Solar Power GmbH

IRAS

Integrated Research Platform for Affordable SatellitesvH&S

von Hoerner & Sulger GmbHTesat Spacecom

Tesat-Spacecom GmbH & Co. KG